From rapid prototyping to high-volume manufacturing, we deliver precision-engineered electronics solutions for the world's most demanding industries.

Discover how we solve complex manufacturing challenges with precision and speed.

Industrial Automation

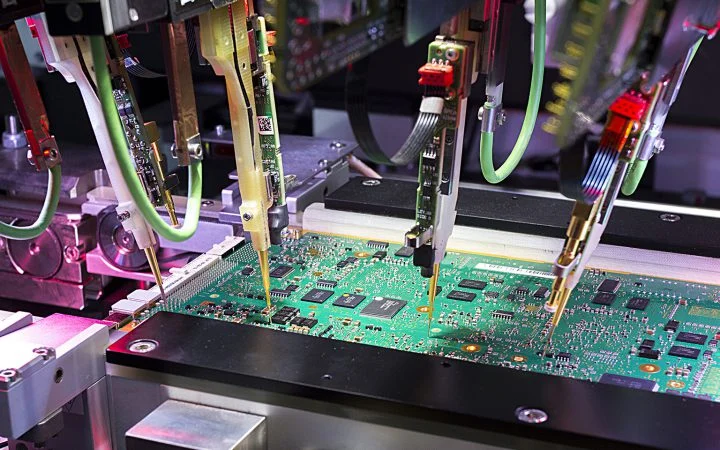

Industrial AutomationComplex multi-layer PCB prototype with integrated power management, multiple ribbon cable connections, and advanced testing protocols. Delivered rapid prototyping with full functional testing within 48 hours.

Consumer Electronics

Consumer ElectronicsState-of-the-art automated assembly line featuring robotic soldering, precision component placement, and real-time quality control. Capable of producing 10,000+ units per day with 99.9% accuracy.

Aerospace & Defense

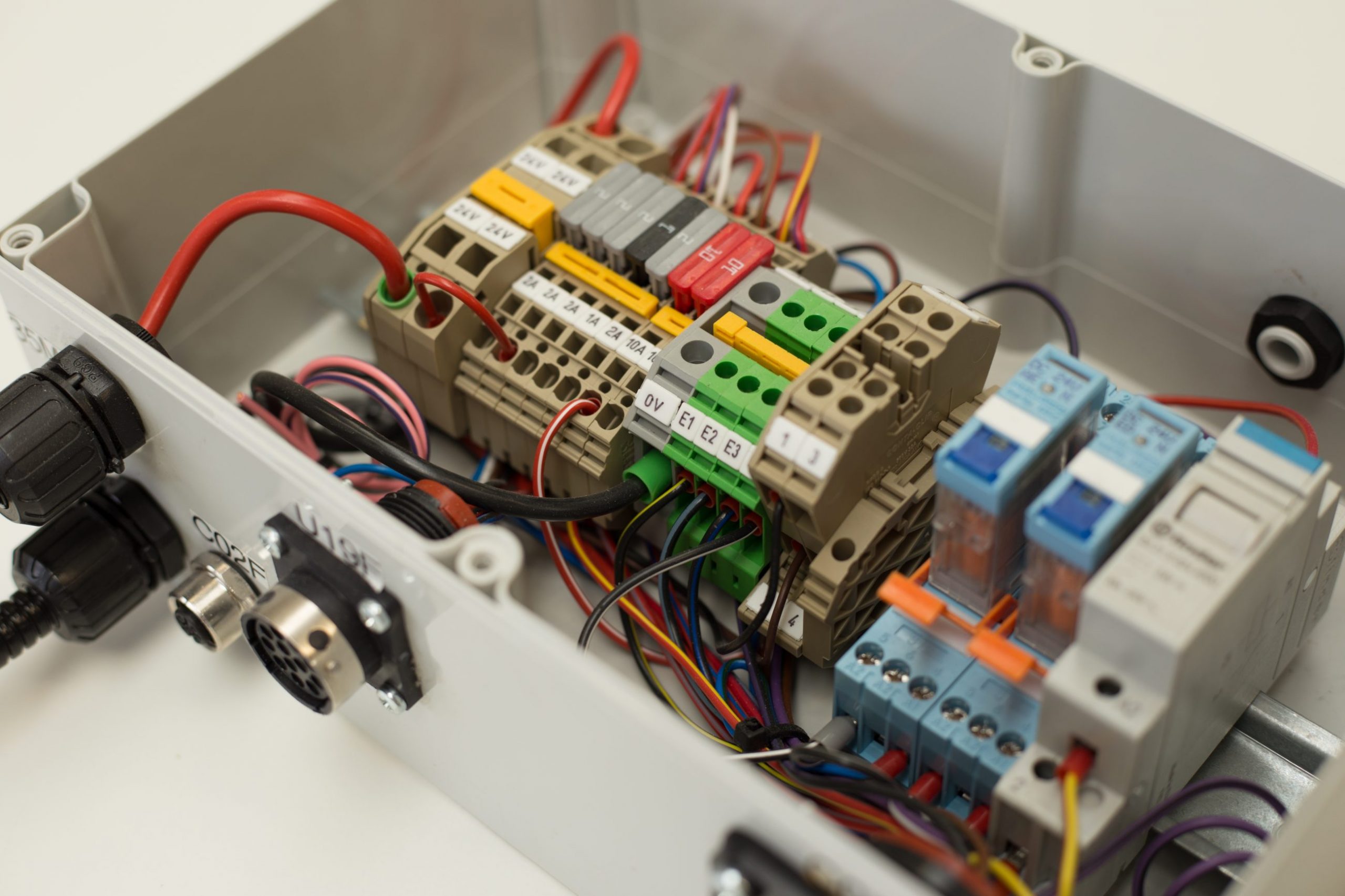

Aerospace & DefensePrecision-engineered wire harness assemblies with custom connectors, color-coded wiring, and rigorous testing. Designed for harsh environments with IP67 protection and military-grade specifications.

Telecommunications

TelecommunicationsHigh-performance multi-conductor cables with shielded construction, precision termination, and extensive testing. Suitable for high-frequency applications and industrial environments.

Medical Devices

Medical DevicesFull system integration including PCB assembly, mechanical housing, power supplies, and final testing. Complete turnkey solution from component sourcing to final product delivery.

Automotive

AutomotiveComprehensive testing protocols including AOI, X-ray inspection, functional testing, and burn-in testing. ISO 9001 certified processes ensuring the highest quality standards.

A breakthrough in rapid medical prototyping. We helped a leading MedTech startup move from concept to clinical trial units in under 3 weeks.

Strict ISO 13485 compliance requirements combined with an extremely tight investor deadline.

Parallel processing of PCB fabrication and component sourcing, utilizing our in-house X-ray inspection for immediate QC.

100% defect-free delivery of 50 prototype units, enabling the client to secure Series A funding.

We invest in the latest manufacturing equipment to ensure precision and reliability.

High-speed pick & place machines capable of 0201 components.

100% visual inspection for component presence and polarity.

Thermal cycling and burn-in chambers for reliability testing.

"Jayshree Instruments delivered our prototypes in record time. Their engineering feedback actually improved our final design significantly."

"The quality consistency for our high-volume run has been impeccable. A true partner in our supply chain."