Manufacturing

The Future

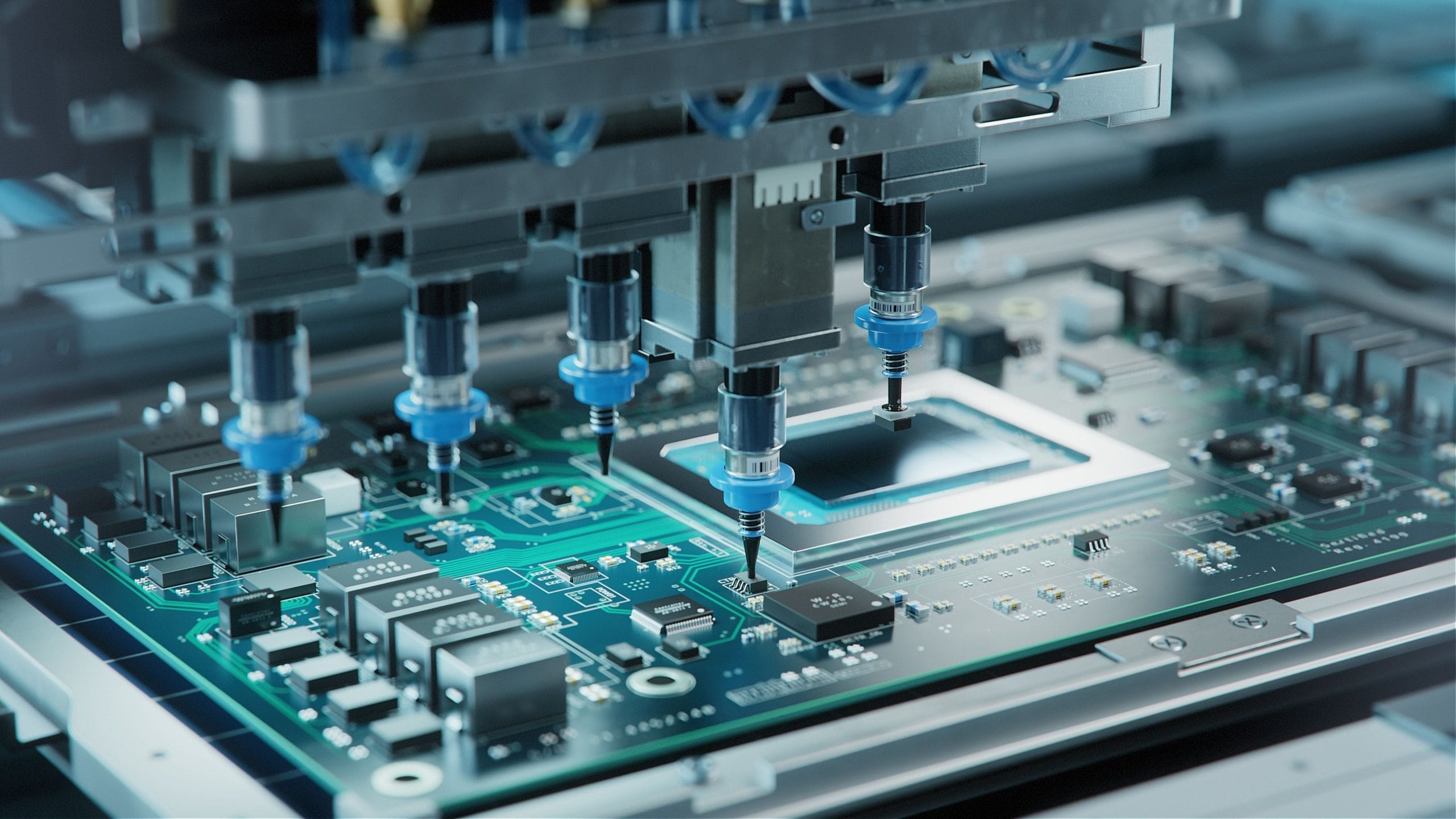

From rapid prototyping to mass production, we deliver precision electronics manufacturing with real-time visibility and ISO-certified quality.

Core Service Stack

From idea to fully shipped product, choose the service tier that matches your current stage.

Tier 1

PCB Assembly

High-quality PCB assembly with SMT & THT capabilities.

Tier 2

Rapid Prototyping

Fast, iterative prototyping to validate your designs.

Tier 3

Wire Harness & Cable Assembly

Custom wire harness and cable assembly solutions.

Tier 4

Design Engineering

DFM/DFT focused design support for reliable products.

How customers use our stack

Most OEMs start with Rapid Prototyping, lock in the design with Design Engineering, and then scale volumes with PCB Assembly + Box Build.

Idea / EVT

Rapid Prototyping + Design Engineering

DVT / PVT

PCB Assembly + Testing & QA

Mass Production

Box Build & Supply Chain

Not sure where to start?

Share your volumes, target markets, and current design maturity. Our engineering team will map the right service stack for you.

Consult Engineering TeamEngineering Excellence

Comprehensive manufacturing solutions designed for scalability, precision, and reliability.

PCB Assembly

High-quality PCB assembly with SMT & THT capabilities.

Rapid Prototyping

Fast, iterative prototyping to validate your designs.

Wire Harness & Cable Assembly

Custom wire harness and cable assembly solutions.

Design Engineering

DFM/DFT focused design support for reliable products.

Box Build & System Integration

Complete product assembly, testing & packaging.

After-Sales Service & Support

Lifecycle support for repairs, upgrades & field returns.

Detailed Service Breakdown

Switch between services to explore features, process coverage, and typical use-cases.

Our Capabilities

Certifications, standards, and in-house controls that keep your builds repeatable, auditable, and production-ready at scale.

ISO 9001:2015 Certified

Quality management system certification

IPC-A-610 Standards

Adherence to industry assembly standards

RoHS Compliant

Environmentally friendly manufacturing

ESD Protected

Electrostatic discharge safe environment

Built for audited, high-reliability programs

Whether you're building for automotive, industrial, or IoT, our processes are aligned with IPC-A-610, RoHS, and ISO-based quality systems. That means fewer surprises in validation and field use.

- Advanced Testing: In-circuit and functional testing capabilities

- Supply Chain Management: Comprehensive component sourcing and management

Transparent

Cost Breakdown

We believe in complete transparency. Our optimized manufacturing processes significantly reduce overhead, putting more value into your actual product.