Understanding Box Build Assembly

Box build assembly, also known as system integration, goes beyond PCB manufacturing. It includes the complete assembly of the final product, such as:

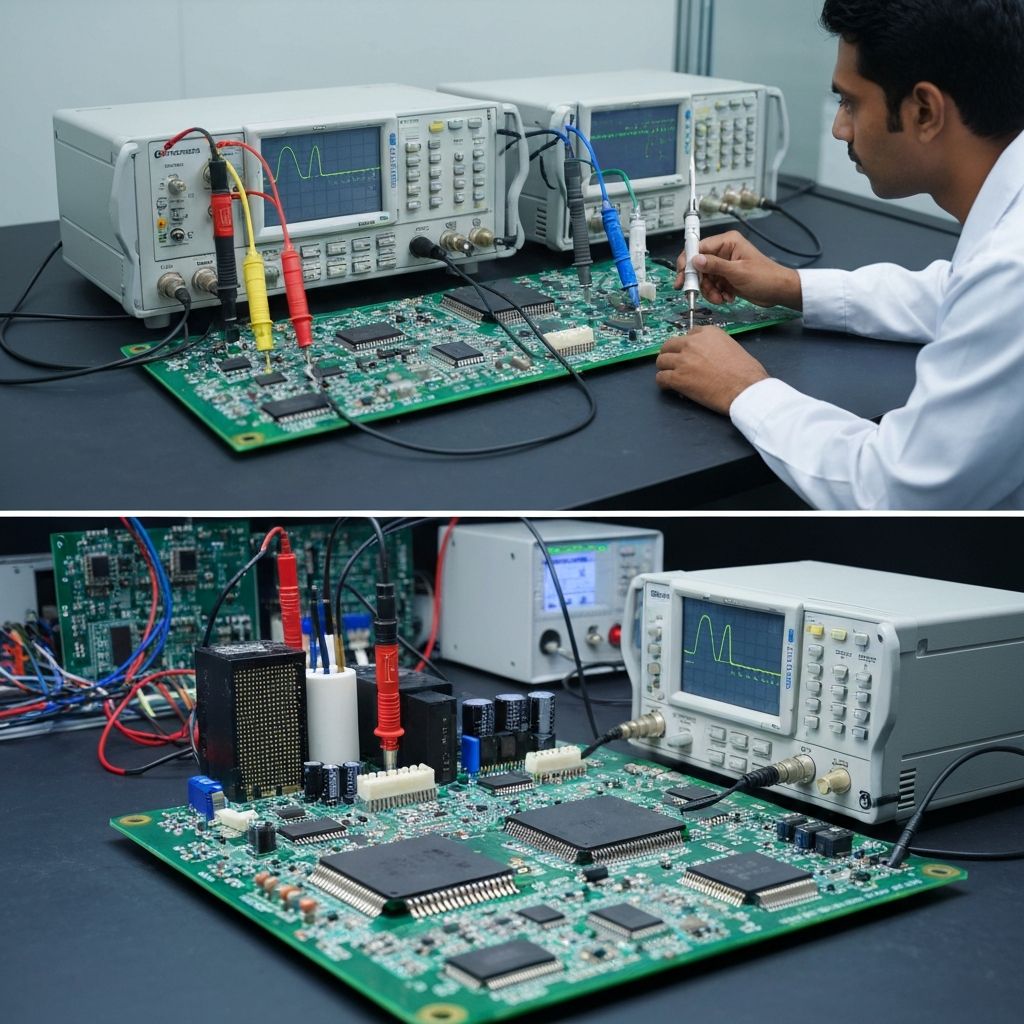

- PCBs and electronics

- Enclosures and panels

- Power supplies, connectors, and wiring

- Displays, switches, relays, and mechanical parts

For industrial automation systems, this is where separate components become a fully functional control unit or machine sub-system.

The Role of Box Build in Industrial Automation

Industrial automation solutions — PLC panels, motor control centers, HMI units, custom controllers — all rely on robust box builds. A well-designed and professionally assembled box build:

- Improves reliability in harsh industrial environments

- Makes installation easier for OEMs and integrators

- Simplifies maintenance and troubleshooting

- Ensures safety and compliance with regulations

Key Elements of a High-Quality Box Build

1. Mechanical Design and Enclosure Selection

The enclosure must be selected based on IP rating, mounting style, size, and environment. Industrial systems may require:

- Metal or polycarbonate enclosures

- Dust-proof and water-resistant housings

- Wall-mount or DIN-rail based designs

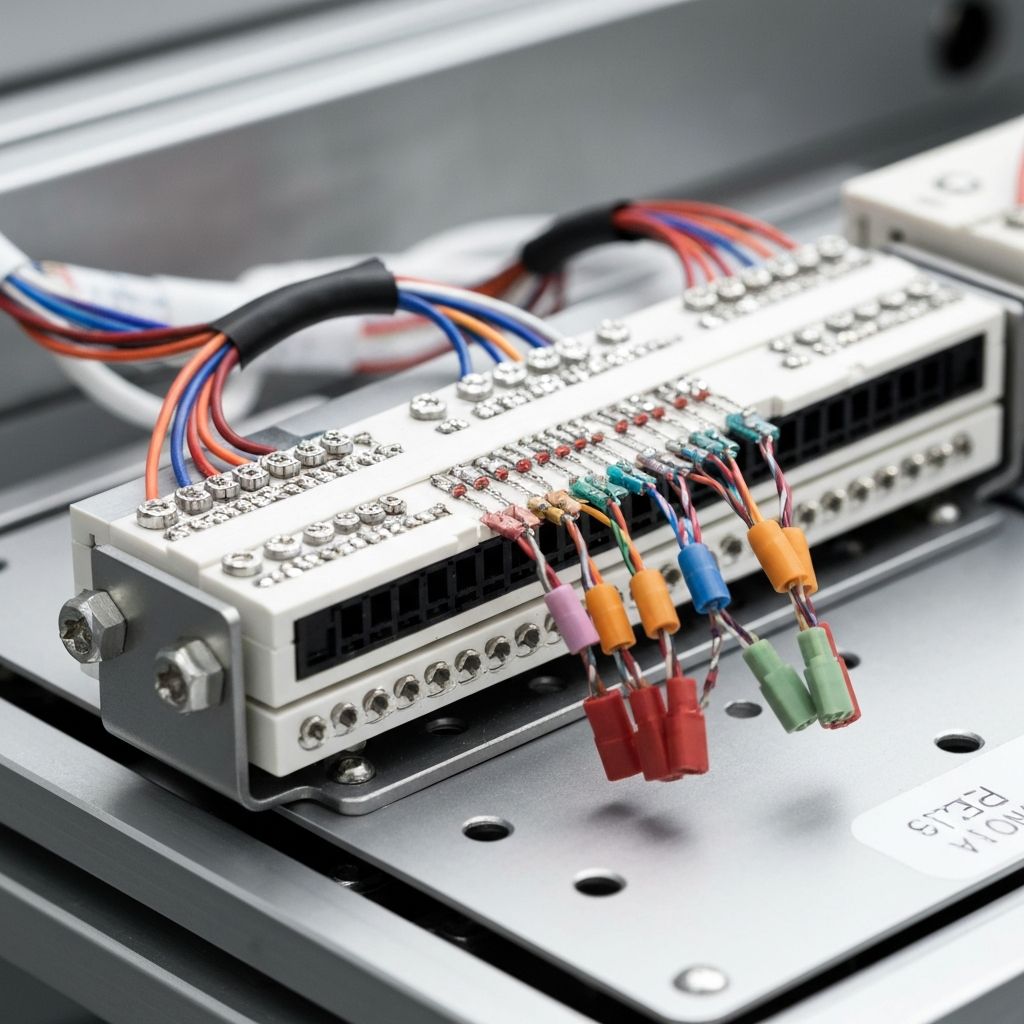

2. Cable and Wire Harness Management

Inside the box, routing of power cables, signal wires, and communication lines must be neat, labeled, and segregated. This reduces:

- EMI and noise issues

- Risk of accidental shorts or damage

- Maintenance time during field service

3. Thermal Management

Industrial automation equipment often operates for long hours in warm conditions. Proper box build design includes:

- Ventilation grilles or fans

- Heat sinks and thermal pads

- Component placement with airflow in mind

4. Safety, Earthing, and Standards

A compliant box build must follow relevant standards (such as IEC, CE, UL, or local norms) and implement:

- Proper earthing and shielding

- Clear labeling and warning signs

- Safe separation between high-voltage and low-voltage sections

Benefits of Outsourcing Box Build Assembly

Partnering with an experienced EMS provider for box build assembly can help OEMs and integrators:

- Reduce in-house assembly workload

- Scale production faster

- Maintain consistent build quality

- Shorten time-to-market for new systems

Conclusion

In industrial automation, a box build is not “just a box” — it is the brain and backbone of the system. Getting it right means fewer breakdowns, safer operation, and happier end customers. Choosing the right EMS partner for box build services makes a direct impact on the long-term success of your automation projects.