What Is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM) is the practice of designing PCBs and products in a way that makes them easy, reliable, and cost-effective to manufacture. Instead of treating design and production as separate stages, DFM creates a tight collaboration between design engineers and manufacturing teams.

Why DFM Is Critical in PCB Design

Good DFM can:

- Reduce manufacturing defects and rework

- Shorten time-to-market

- Lower overall production cost

- Improve yield and consistency across batches

Key DFM Principles for PCB Design

1. Component Selection and Availability

Choosing exotic or hard-to-source components can create supply chain risk. Work with your EMS partner to:

- Use standard, widely available footprints

- Confirm second-source options for critical parts

- Avoid components nearing end-of-life (EOL)

2. Proper Pad and Footprint Design

Incorrect pad sizes, missing solder mask clearances, or inconsistent footprints are common causes of soldering issues. Follow IPC guidelines and your EMS partner’s recommended footprint library wherever possible.

3. Clear Spacing and Routing Rules

Ensure sufficient spacing between tracks, pads, and vias based on your PCB manufacturer’s capabilities. Tight spacing increases:

- Risk of shorts or opens

- Manufacturing complexity and cost

- Inspection difficulty

4. Consider Panelization and Board Shape

Odd-shaped boards, sharp internal cutouts, or complex outlines can complicate fabrication and assembly. Involve your EMS provider early to:

- Optimize panel layout

- Add break-away tabs, mouse bites, or V-cuts

- Ensure efficient use of PCB material

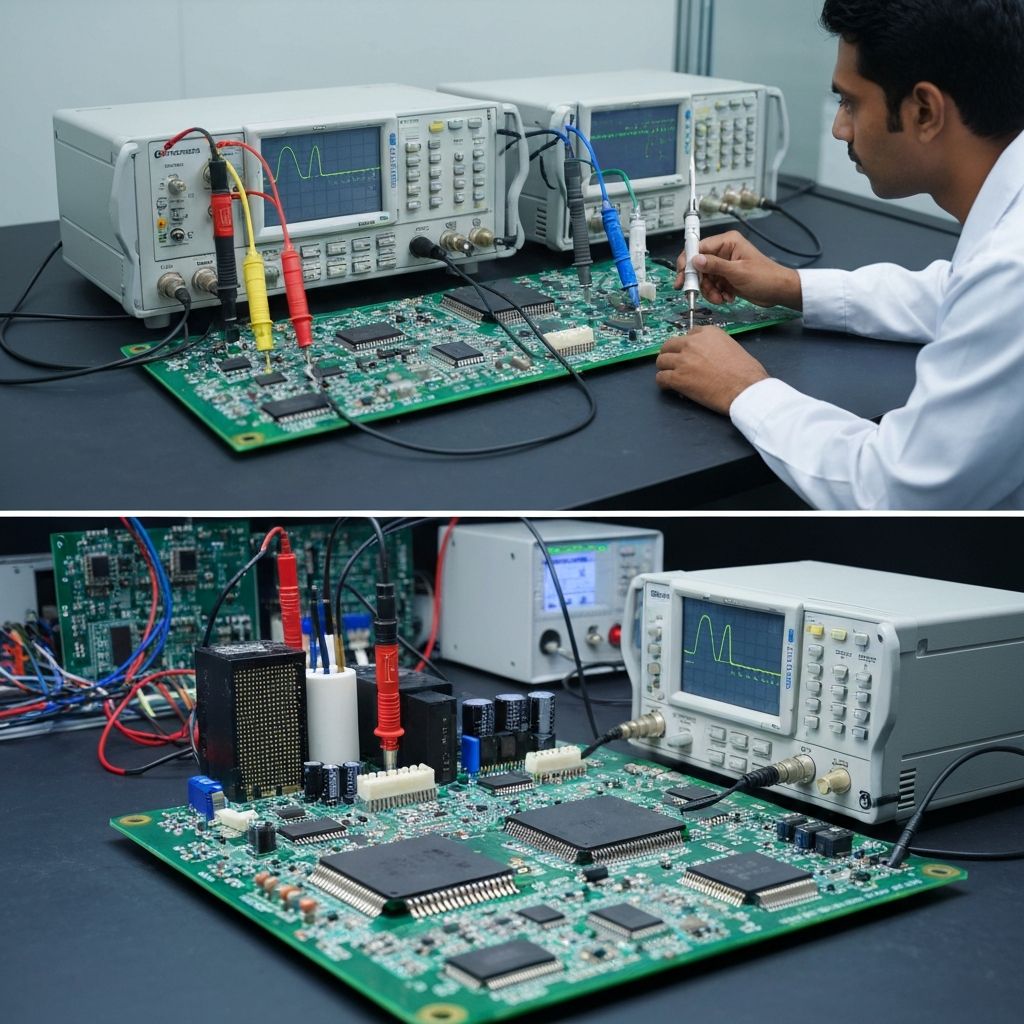

5. Design for Testability (DFT)

Testability is a core part of DFM. Without adequate test points or access, ICT and flying probe tests become difficult or impossible. Add:

- Clearly labeled test points for key nets

- Accessible programming headers

- Provisions for boundary scan where applicable

DFM Review with Your EMS Partner

Before freezing your PCB design, request a DFM review from your chosen EMS vendor. They will check:

- Fabrication constraints (layer stack, drill sizes, tolerances)

- Assembly feasibility (component spacing, orientation, reflow behavior)

- Inspection and testing access

This review often saves weeks of rework and multiple prototype spins.

Conclusion

DFM is not just a technical checklist — it is a mindset. By involving your manufacturing partner early and designing with production in mind, you can build products that are scalable, reliable, and cost-efficient from day one.