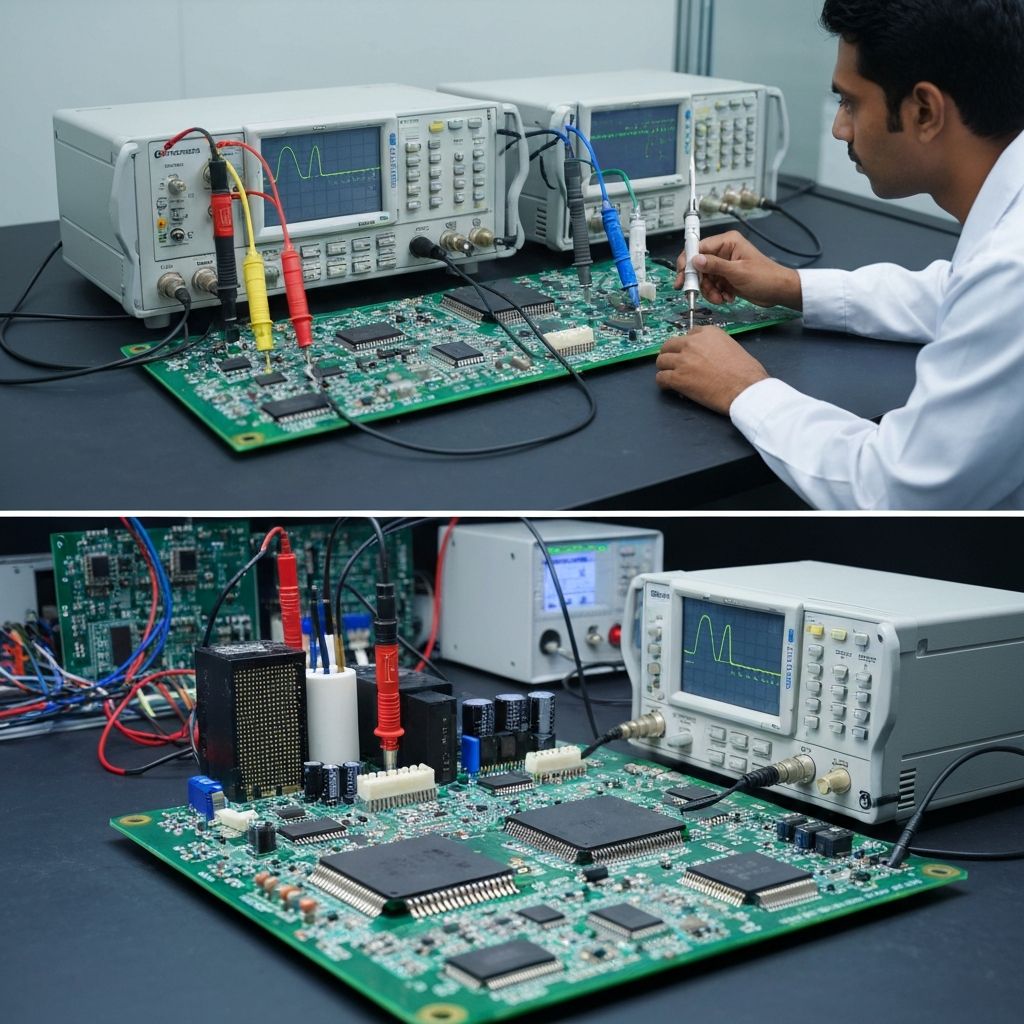

Automation in PCB Assembly: The Big Picture

PCB assembly lines have evolved from semi-manual processes to highly automated, data-driven production systems. Today’s factories combine SMT machines, inspection systems, and MES/ERP integrations to deliver faster and more consistent output.

Trend 1: Higher-Speed SMT Lines

Modern pick-and-place machines can handle:

- Very small components (01005, micro-BGAs)

- High placement rates while maintaining accuracy

- Automatic reel changeovers and feeder optimizations

Trend 2: Intelligent Reflow Profiling

Reflow ovens now support advanced profiling and closed-loop control. Benefits include:

- Stable solder joints across varying PCB designs

- Reduced risk of tombstoning and voids

- Energy-efficient oven operation

Trend 3: AOI and SPI Integration

Solder Paste Inspection (SPI) and AOI are increasingly integrated into the line, enabling:

- Real-time process feedback on paste volume and placement quality

- Automatic adjustments to print parameters

- Early detection of defects before reflow

Trend 4: Industry 4.0 and Data Analytics

PCB assembly machines now generate rich data that can be analyzed for:

- Predictive maintenance of equipment

- Yield tracking by product, shift, or component

- OEE (Overall Equipment Effectiveness) optimization

Trend 5: Flexible Automation for Mixed-Volume Production

With more product variants and shorter life cycles, EMS providers are investing in flexible automation:

- Quick-change fixtures and feeders

- Modular production cells

- Robotic material handling and labeling

Conclusion

Automation in PCB assembly is no longer optional — it is a competitive necessity. By choosing EMS partners who invest in modern equipment and data-driven processes, you gain better quality, consistency, and scalability for your products.