Understanding Volume in PCB Assembly

Not all PCB assembly projects are the same. A batch of 20 prototype boards and a yearly demand of 100,000 units require completely different production strategies. Choosing the right EMS setup helps you control cost, lead time, and quality.

Low-Volume PCB Assembly

Low-volume typically refers to:

- Prototypes and engineering validation builds

- Pilot batches for field trials

- Specialized or niche products with limited annual demand

Key Characteristics

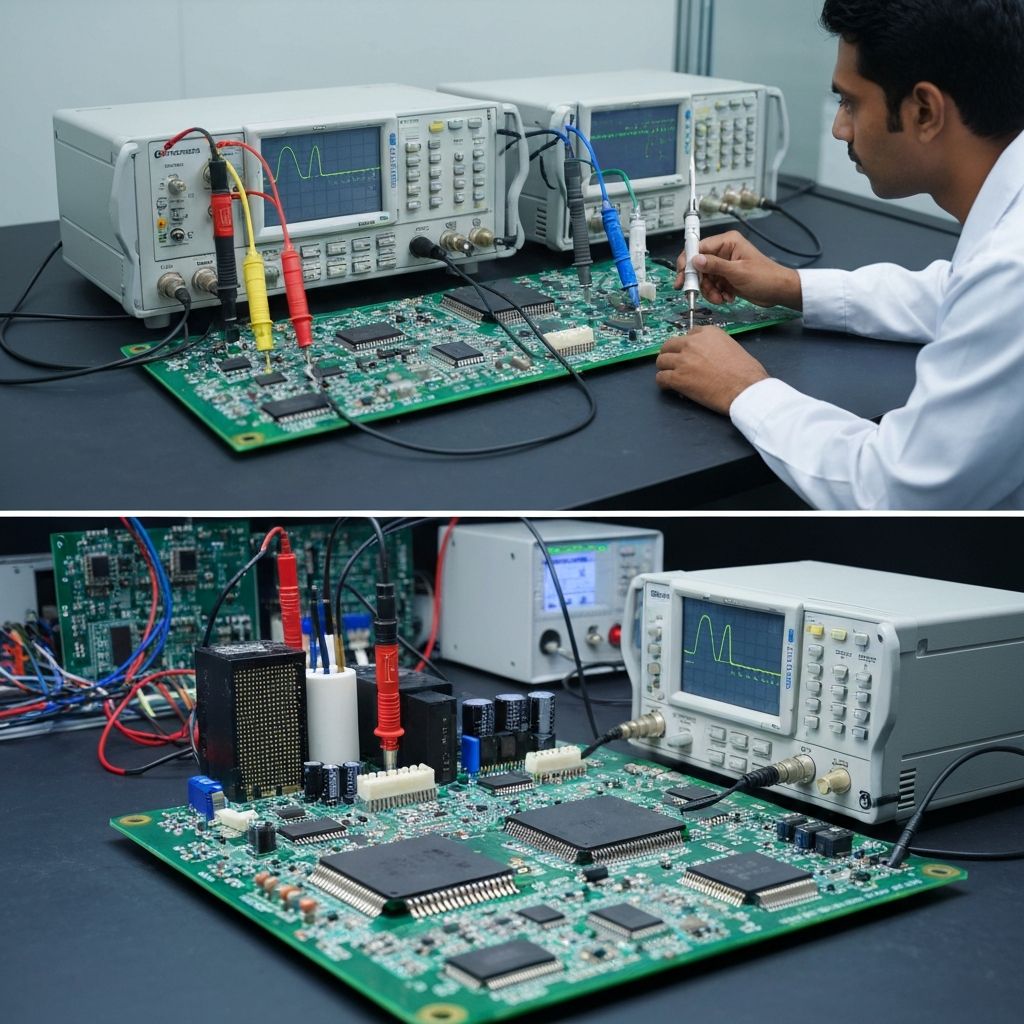

- More manual or semi-automatic processes

- Flexible setups, frequent changeovers

- Higher per-unit cost, but lower upfront investment

High-Volume PCB Assembly

High-volume manufacturing focuses on scaling a proven design. It is ideal when:

- Design is frozen and stable

- Annual demand is high or growing

- Per-unit cost becomes a major competitive factor

Key Characteristics

- Highly automated SMT and inspection lines

- Dedicated fixtures and test setups

- Lower per-unit cost, but requires higher upfront planning and tooling

DFM and NPI: Bridging the Gap

A good EMS partner will guide you from low-volume NPI (New Product Introduction) to high-volume production through:

- DFM reviews and design optimization

- Controlled process validation runs

- Gradual ramp-up of volumes

Conclusion

Both low-volume and high-volume PCB assembly have their place in a product’s lifecycle. Understanding the differences helps you pick the right approach at each stage, from early prototypes to mature mass-produced products.