What Is Shielding in Cable Assemblies?

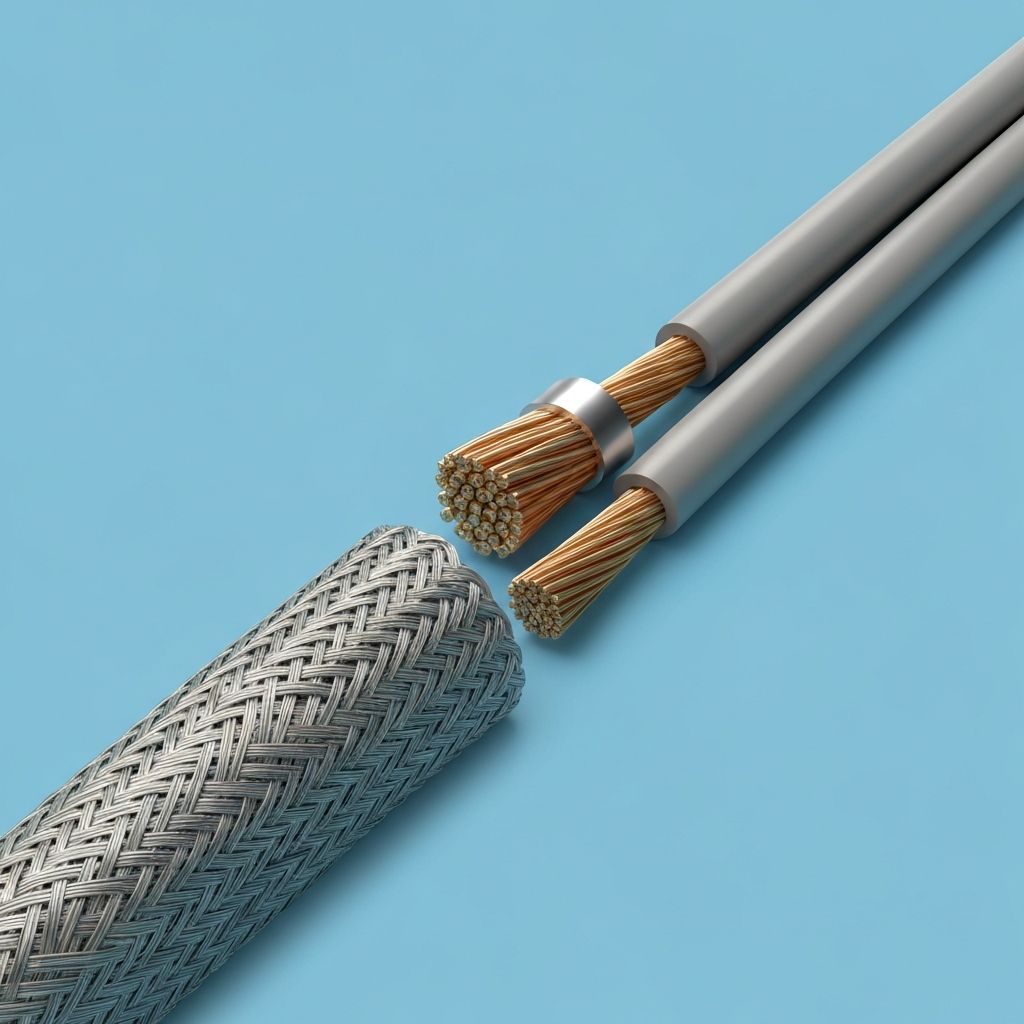

Shielding is a conductive layer (foil, braid, or a combination) that surrounds the inner conductors of a cable. Its main purpose is to protect signals from external electromagnetic interference (EMI) and to reduce emissions from the cable itself.

Unshielded Cables: When They Are Enough

Unshielded cables are simpler and more economical. They are suitable when:

- Signal frequencies are low

- Cable runs are short

- Electrical noise in the environment is minimal

- Regulatory EMI requirements are not very strict

Shielded Cables: When You Need Extra Protection

Shielded cables are preferred for:

- High-speed data lines (Ethernet, serial, fieldbus)

- Sensitive analog signals (sensors, instrumentation)

- Industrial environments with motors, VFDs, and welders

- Compliance with EMC regulations

Types of Shielding

- Foil shields – good for high-frequency noise, lightweight, cost-effective.

- Braid shields – better mechanical strength, good low-frequency noise rejection.

- Combination shields – foil + braid for wider spectrum protection.

Pros and Cons at a Glance

Shielded Cables

- Pros: Better EMI protection, improved signal integrity, required in noisy environments.

- Cons: Higher cost, slightly more difficult to terminate, larger cable diameter.

Unshielded Cables

- Pros: Lower cost, easier handling and termination, smaller size.

- Cons: More vulnerable to electrical noise and emissions.

How to Choose for Your Application

Consider the following factors:

- Signal type and speed

- Distance and routing (near power cables or motors?)

- Regulatory requirements (CE, FCC, industry standards)

- Budget vs. risk of communication issues

Conclusion

The choice between shielded and unshielded cable assemblies is not one-size-fits-all. By understanding your electrical environment and performance requirements, you can make an informed decision that balances cost, reliability, and compliance.