What Is a Wiring Harness?

A wiring harness is an organized bundle of wires, cables, connectors, terminals, and protective coverings that transmit power and signals in an electrical system. Instead of running individual loose wires, harnesses create a structured, safe, and serviceable wiring solution.

Why Wiring Harnesses Are Used

- Improve safety by securing and protecting conductors

- Reduce assembly time on the production line

- Enhance reliability and reduce risk of loose connections

- Simplify maintenance and troubleshooting

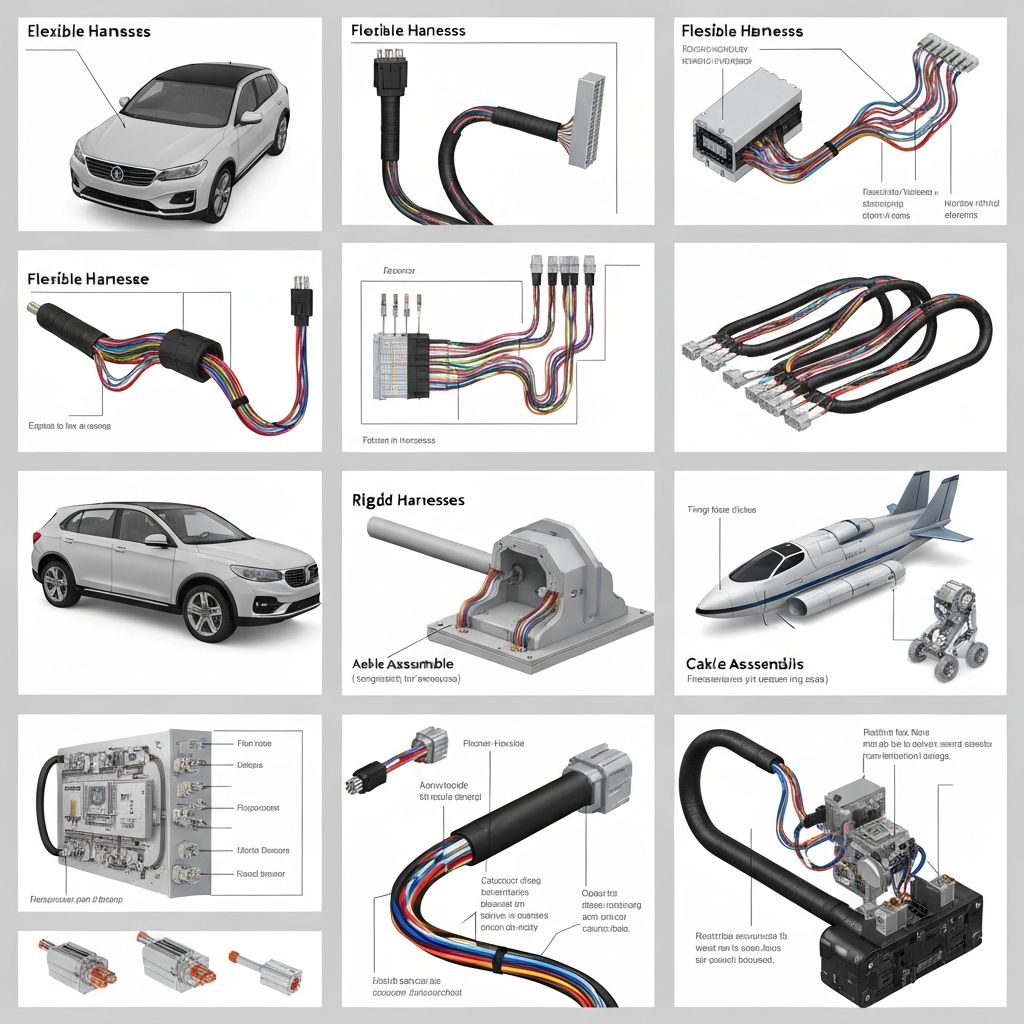

Common Types of Wiring Harnesses

1. Engine and Powertrain Harnesses

Used in automotive and off-highway vehicles, these harnesses connect sensors, actuators, ECUs, ignition systems, and power distribution components. They must withstand:

- High temperatures and vibration

- Oil, fuel, and chemical exposure

- Water and dust ingress

2. Dashboard and Interior Harnesses

These harnesses connect instrument clusters, infotainment units, lighting, switches, and HVAC controls. Focus areas include:

- Ergonomic routing behind panels

- Noise-free audio and communication lines

- Safe integration with airbag and safety systems

3. Industrial Machinery Harnesses

Used inside control panels, machinery, and factory automation systems, these harnesses route:

- Power circuits to motors and drives

- Control signals to sensors and actuators

- Communication lines (Ethernet, fieldbus, serial)

4. Medical Device Harnesses

Medical harnesses support diagnostic equipment, patient monitors, and lab instruments. They demand:

- High reliability and redundant paths in some cases

- Specialized materials and safety ratings

- Careful EMI/EMC design practices

5. Telecom and Data Harnesses

In telecom cabinets and IT racks, harnesses carry data, control, and power. Typical requirements include:

- High-density connectors

- Organized patching and labeling

- Low-loss, high-bandwidth cables

Key Design Choices Across Harness Types

- Wire gauge and insulation type

- Connector systems and locking features

- Protective coverings (looms, braids, conduits)

- Labeling, marking, and documentation

Conclusion

From cars and industrial machines to telecom networks and medical devices, wiring harnesses quietly keep everything connected and operational. Understanding the different types helps you specify the right harness for your next project — and partner with a manufacturer who can deliver reliably at scale.