Why Wire Harnesses Are So Important

Industrial machinery relies on a complex network of power, control, and communication signals. Wire harnesses bring order to this complexity, bundling cables into a neat, reliable, and maintainable structure.

Common Applications in Industrial Environments

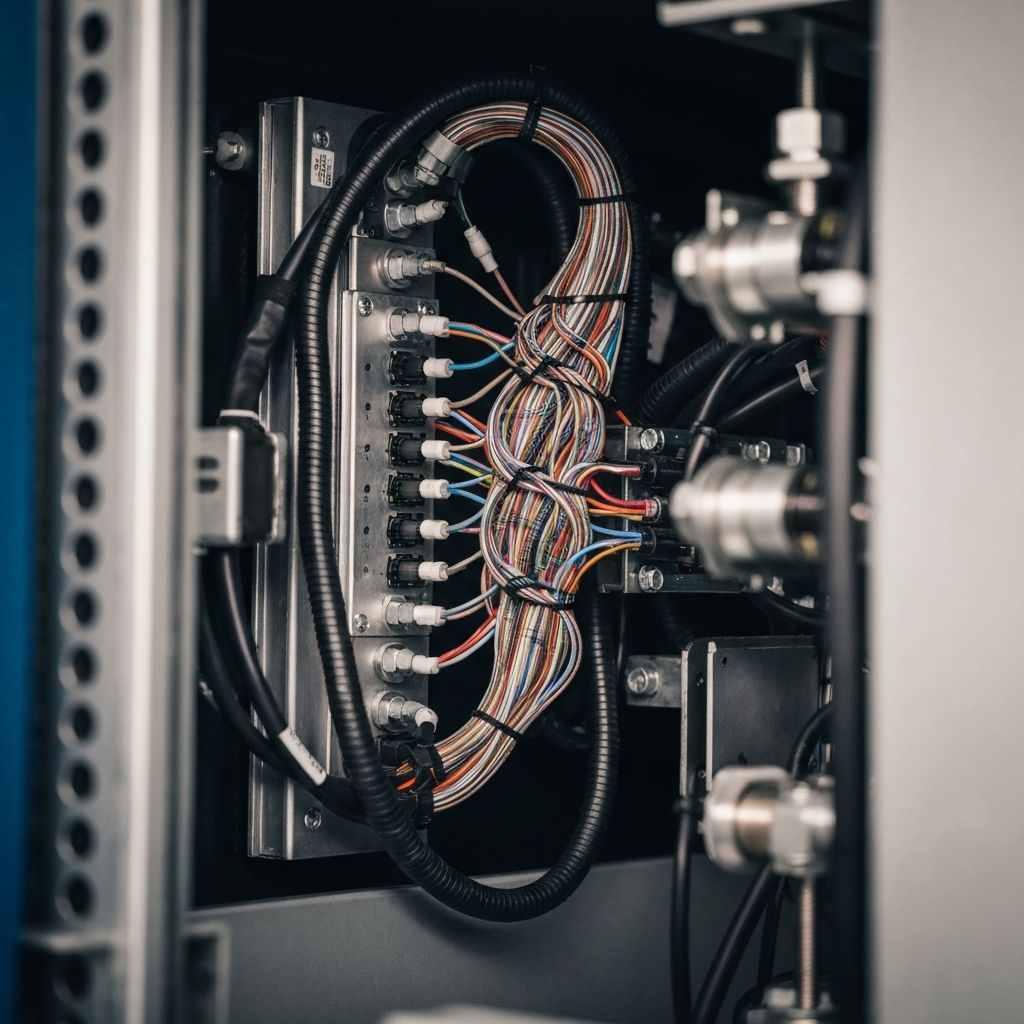

1. Control Panels and PLC Cabinets

Harnesses inside control panels connect PLCs, relays, power supplies, contactors, and field connection terminals. Good harnessing reduces downtime and simplifies troubleshooting.

2. CNC Machines and Robotics

Dynamic harnesses support moving axes, spindles, tool changers, and sensors. These often require:

- High-flex cables

- Drag-chain compatible designs

- EMI-aware routing

3. Conveyors and Material Handling Systems

Motors, encoders, sensors, and safety devices across long conveyor lines are interconnected via modular harnesses and junction boxes, enabling quick installation and expansion.

4. Process Equipment and Packaging Machines

Temperature sensors, level switches, valves, drives, and HMIs all depend on robust harnesses designed to handle vibration, moisture, and frequent cleaning.

Design and Environmental Considerations

Industrial harnesses must be designed for:

- Mechanical protection using conduits, sleeves, and grommets

- Proper segregation of low-level signals and high-power lines

- Resistance to oils, chemicals, dust, and humidity

Conclusion

Wire harnesses are the circulatory system of industrial machinery. Investing in professional design and manufacturing of harnesses directly translates into fewer breakdowns, safer operation, and lower maintenance costs over the life of the equipment.